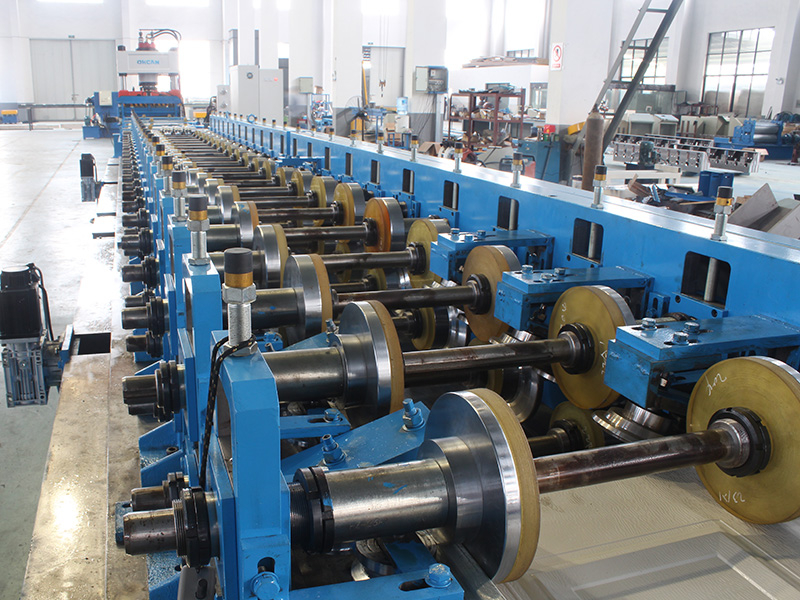

Stations: 28

Rollers material: CR 15, HRC 60. Chrome coated: 0.03-0.05mm, Strength (MPA): 70 tons, 800 MPA

Shaft: diameter 65mm, material is #45 steel. Quenched hot treatment. Strength of the main shaft (MPA): 70 tons, 650MPA

Bearing brand: FAG Germany

Main motor: 7.5KW*2, 220V/380V, 50HZ/60HZ, 3 Phases (Siemens Brand),

Transmission by gear

Station material: cast steel

Automatic adjust width by servo

Dimensions of the final product: 430-650mm

Material: pre-painted galvanized steel (thickness from 0.45 to 0.75 mm)